ELECTRIC COLD STORAGE FLOOR HEATING

Cold storage spaces have their own unique environmental climates and need to be separated from surrounding spaces to avoid condensation and ice formation. While proper insulation and a vapour barrier are essential to minimise heat escaping, they do not fully prevent it.

Overview

Devex Systems offers heating cables for freezers and coolrooms specifically designed to generate the heat necessary for use in these specific environments. These heating cables both prevent potential damage and safety issues. Electrical heating cables can be used in four different situations:

Frost Heave Protection

Issue

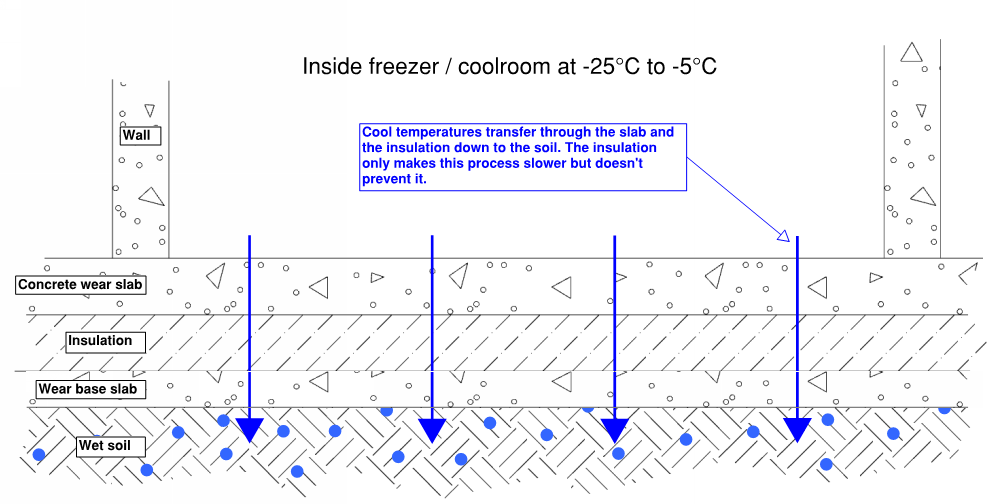

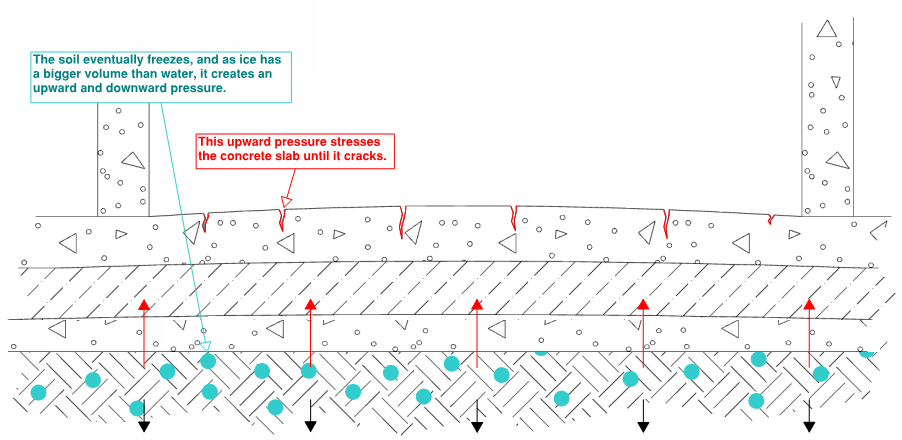

Frost heaving (or frost heave) appears when water freezes under a ground slab. As ice has more volume than water, it puts upward pressure on the slab.

- When the freezer is activated, the cool temperatures absorbs the heat from the soil, decreasing the soil temperature until moisture freezes.

As ice has more volume than water, the soil expands and puts downward and upward pressure on the slab until it eventually fractures.

Fractures in the slab decreases the insulation of the cold storage space and increases electricity consumption to keep the freezer/coolroom at the desired temperature. A heaved slab can also be dangerous in a high traffic area such as forklift transit area and needs immediate replacement.

Solution

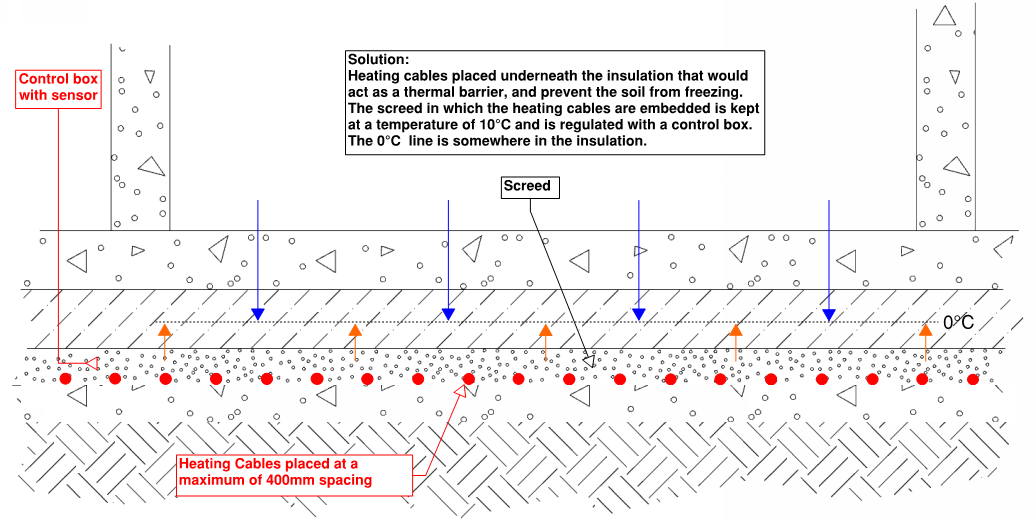

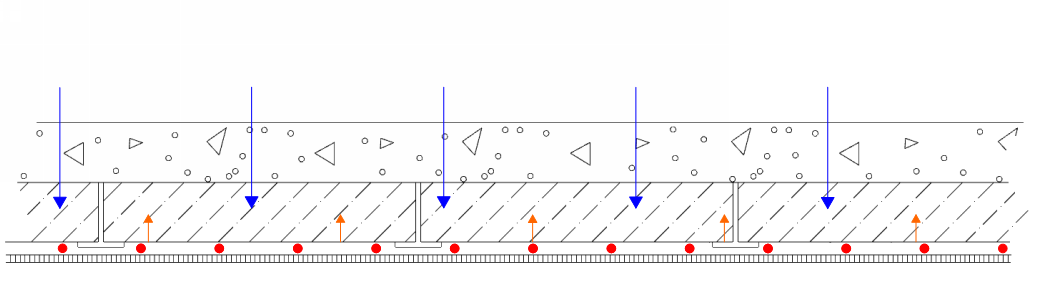

Place electric heating cable under the insulation to prevent the soil from freezing.

As the cables are imbedded into a thick concrete slab, we recommend installing a twin-cable heating system as a fail-safe. One cable is on standby in case of cable failure.

Devex Systems offers different freezer heating solutions depending on your need:

- DIY Heating Cables: Two cables are included with detailed procedures provided on the confirmation order. The information includes cable installation, spacing and wattage. One cable needs to be connected to the control box, while the other is used as a spare, in case the first cable fails.

- Ready-To-Go Heating Mats: Two heating cables are placed on chicken mesh and cut according to freezer size. The mesh is laid down and the cable connected to the control box. This is an ideal solution if you are not accustomed with laying down single conductor heating cables.

The control box that comes with the cables is specially designed for freezer applications. It contains 2 thermostats, with one set up at 5°C, and the other at 10°C. The first thermostat is linked to an alarm device (supplied by the customer) and notifies in case of cable malfunction when the temperature reaches below 5°C. In this case, a licensed electrician needs to switch the system to the standby cable. The second thermostat is used to regulate the temperature of the floor.

Condensation Prevention

Issue

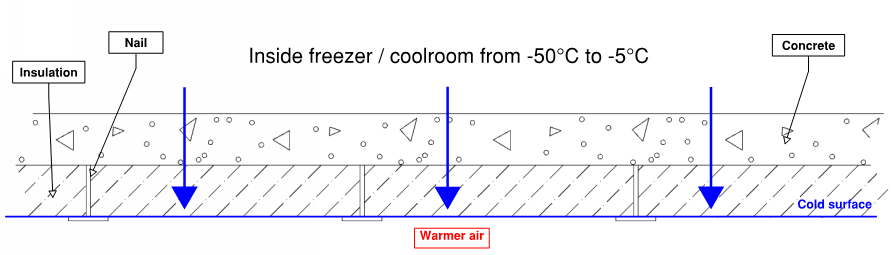

While frost heave may occur on ground slabs, condensation can happen with suspended slabs. Condensation takes place when hot air encounters a cold surface (similar to morning dew when air gets warmer and surfaces remain cold).

In the case of a freezer on a suspended slab, the bottom of the slab will eventually get cold, despite having insulation underneath. Since insulation only slows the temperature transfer and does not prevent it, condensation will appear.

Solution

Because condensation appears on cold surface, the best solution is to heat up the cold surface. Devex Systems offer a range of heating cables that can be fastened beneath the suspended slab.

Freezer Door Threshold

Issue

All previous issues dealt with heat transfer through the slab. However, there are other more obvious cases where heat transfer occurs. For example, an open freezer doors can push cold air into a room and easily freeze any trace of water on the floor, creating a potential hazard.

Solution

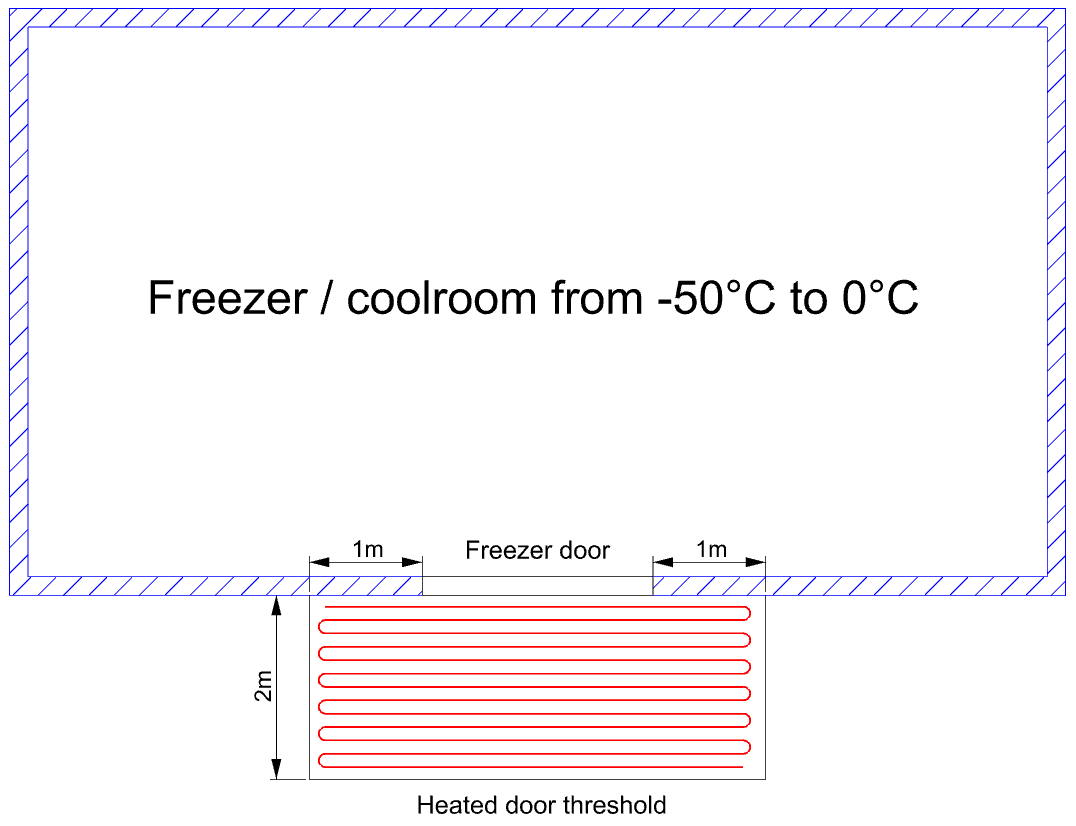

Devex Systems offers the X Cable CT specially designed to place into the slab. These cables are rated at 30 Watts per metre. The spacing should be 100mm for an output of 300 Watts per square metre. The customer determines the size of the area, but other factors are taken into consideration such as temperature inside and humidity outside the freezer. A standard installation would look like the following:

Heat Tracing For Freezer

Issue

Other issues can occur in cold storage spaces that may require a more complex heating system than what simple floor heating can offer. For example, a freezer door can freeze shut due to ice formation on the doorframe or ice formation inside drain lines.

Warehouse freezer door covered in ice and frost

Solution

Devex Systems offers two different types of heat tracing cables:

- Self-Limiting Cable: This cable can be cut to any length without damage to the cable. The power output depends on the surrounding temperature. The lower the temperature, the higher the output.

- Silicone Cable: This cable is custom made to specific length, wattage and termination requirements. The maximum power output is 40 W/m. These cables offer an affordable alternative to self-limiting cables, but are not as flexible to use. Whilst self-limiting cables can be cut to any length without issues, cutting a silicone cable shorter than needed will increase its power output and risk overheating the cable (Note: as a rule of thumb, cutting a cable in half will increase its power output by 2).

Uses for Heat Tracing Cables

The amount of heat (wattage) required will vary depending on the application. For example, heat trace cables rated from 25 to 40 Watts per metre are commonly used for walk-in freezers with an operating temperature of -30°C. Reach-in and walk-in freezers that work at higher temperatures generally need cables rated from 10 to 20 Watts per metre.

Note: these wattages are general recommendations only. Each installation is unique and careful testing using thermocouples should be carried out to ensure a proper and safe application.